The modern automotive transmission consists of thousands of components. Many argue transmissions are even more complicated than engines! This comprehensive guide aims to inform readers on various topics relating to transmission operations, failures, diagnostics, and repairs. Want to learn more about a specific issue you are experiencing? Browse our table of contents and select what you need, or continue reading to get started!

Table of Contents:

-

Automatic Transmissions

- Difficulty Shifting

- Slipping Gears

- Noisy Shifts

- Bad Smells

- CEL (Check Engine Light)

- Leaking Fluid

-

Manual Transmissions

- Difficulty Shifting

- Clutch Drag

- Noise Shifts

- Leaking Fluid

- CEL (Check Engine Light)

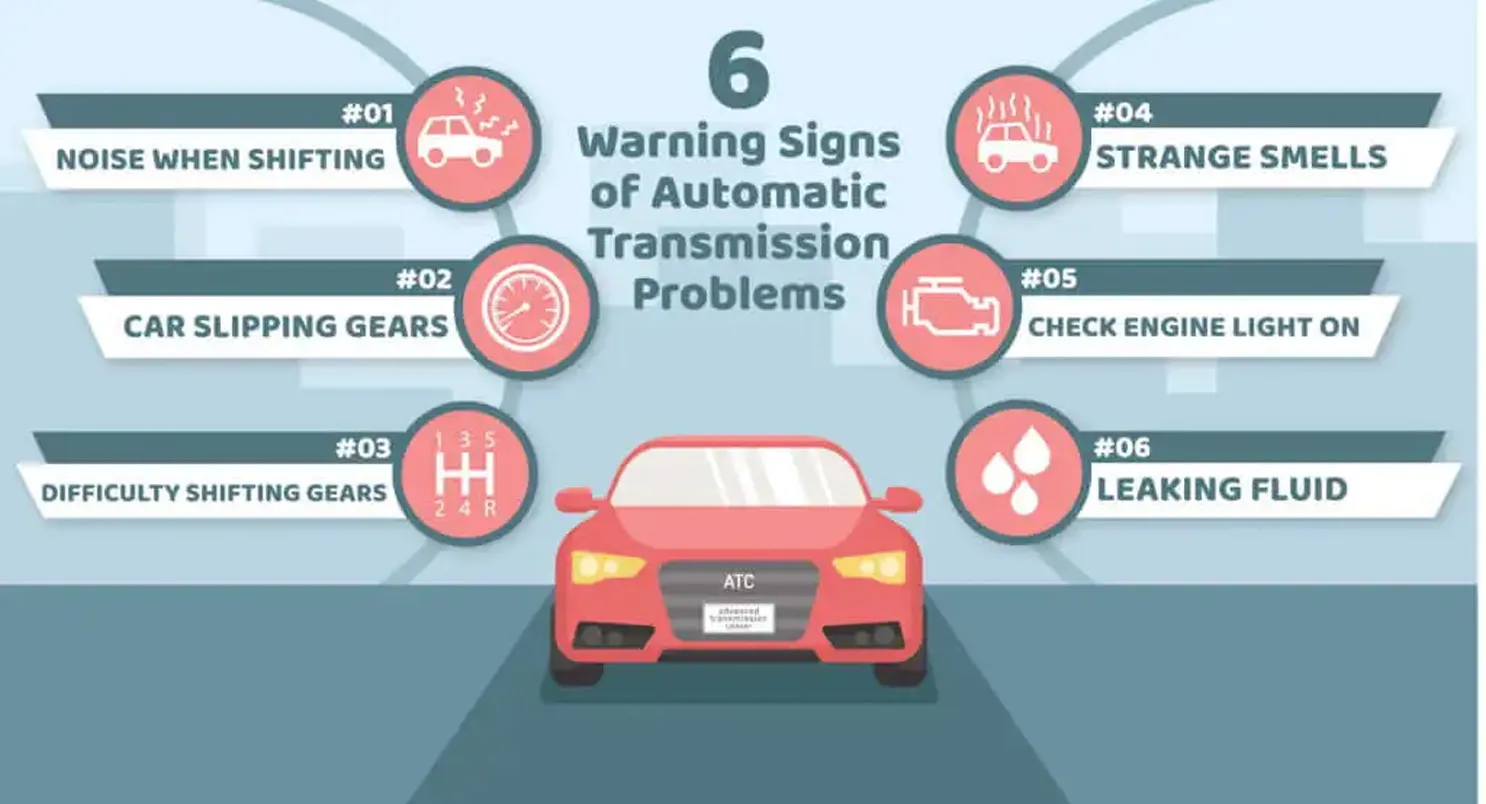

Automatic Transmission Problems

1. Making Noise When Shifting

If your transmission is making noise when shifting, it’s important to determine the type of sound to begin properly diagnosing the issue. Does the sound resemble humming, buzzing, whining, or clunking? These are most commonly used to describe transmission failure noises. With thousands of parts in a transmission, a single bearing or even a worn case can emit a troubling noise. Unfortunately, these noises are more than just annoying. They ultimately lead to transmission failure. Often, bad automatic transmissions will emit humming, buzzing, or whining sounds. Also, a grinding noise when changing gears is a sure sign of internal problems and should never be ignored.

When metal begins to grind on metal, catastrophic failure is close behind. Pay attention to the sound of your transmission in neutral. Does your transmission “bump” or quake? Some noises, such as a “bump,” require adding or changing the automatic transmission fluid or some other simple fix. Other times, however, a more serious issue is at hand. Many Chrysler vehicles, including Dodge and Jeep brands, require fluid inspection in neutral.

2. Car Slipping Gears

Transmission slipping usually takes two forms: erratic shifting between gears and underperforming acceleration. Slipping gears is fairly common and easy to identify. For example, have you ever been cruising along when, out of the blue, your vehicle unexpectedly changes gears? If you answered “Yes,” you have experienced gear slipping. Underperforming acceleration is another example of gear slipping. When your car struggles to accelerate or feels weak and underpowered, the gears inside the transmission are not shifting properly, and thus are slipping.

Many modern transmissions will prevent a driver from driving with a damaged transmission by going into “limp mode” or “safe mode.” Under this circumstance, the computer system will detect a problem with the transmission and default to one gear. The vehicle will not shift between gears and will only operate in one gear, often 3rd gear, as a safety mechanism to allow the driver to get the vehicle in for repair immediately. Replacing the transmission fluid is often a quick transmission slipping fix.

3. Difficulty Shifting Gears

If shifting seems to take longer than normal or your vehicle seems to struggle to shift smoothly, you should see a mechanic. Remember, shifting gears should be virtually unnoticeable in newer vehicles under normal throttle. In an older vehicle, feeling a slight difficulty shifting gears is okay. However, any dramatic shift could indicate a problem is present.

If you find yourself wondering why the RPMs keep rising without getting to the next gear, that’s another indication that the internal clutches of the transmission are worn and the transmission cannot engage the gear commanded by the computer system. Observing any single symptom is not sufficient to diagnose the issue. In some cases, a hard shift could be inaccurately diagnosed as a transmission failure when, in fact, an engine or transmission mount has failed. In this example, the engine jolts back and forth when the vehicle shifts gears, and the RPMs simultaneously drop or rise. Don’t waste thousands of dollars because of a misdiagnosis; trust the specialists at your local transmission shop!

4. Odd Scents & Strange Smells

Burning odors usually mean your transmission fluid is overheating due to clutch debris, breakdown of metallic components, and sludge. If your transmission fluid has not been flushed or serviced on a vehicle with over 100,000 miles, this is a common outcome. How will you know what burnt transmission fluid smells like? When Automatic Transmission Fluid (ATF) burns, it omits a uniquely acrid smell, closer to the stench of burning rubber than burning oil. If the transmission fluid gets extremely hot, you may even observe smoke. Once the fluid is burnt, it can no longer perform its job of managing heat, lubricating parts, and hydraulically shifting gears.

5. Check Engine Light On

The transmission light on a car can indicate overheating problems caused by worn parts or low fluid levels. Beyond the possibility of transmission issues, your vehicle’s Check Engine Light is designed as an incredible early indication of a problem. Do not ignore this warning sign, and do not assume that the warning light came on for no reason. The service light on your dashboard responds to sensors placed at crucial points inside the vehicle. These sensors detect unusual data readings that you may not detect while driving. Don’t wait for your vehicle to begin grinding and trembling; if the Check Engine Light turns on, it is best to take your vehicle to a repair shop you trust for an accurate diagnosis right away. In some cases, a diagnostic code could point to a minor repair that prevents a major (and costly) repair.

For example, a P0944 Loss of Prime or Hydraulic Pressure Unit Loss of Pressure could be resolved by adding more fluid and potentially addressing a leak. If not addressed immediately, a low fluid condition can lead to overheating and internal damage. In other circumstances, a diagnostic code tells a technician a major repair (e.g., transmission rebuild or replacement) is required. A P0730 Gear Ratio Incorrect code may point to irreparable internal damage that requires a transmission replacement or rebuild/overhaul.

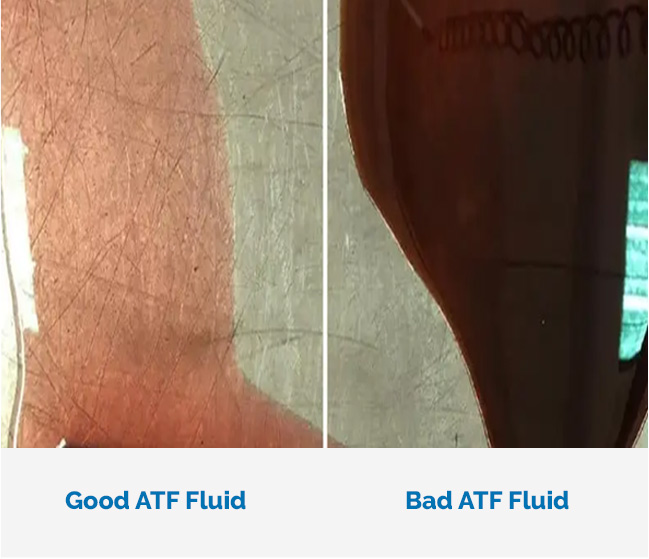

6. Leaking Fluid

Leaking fluid is recognizable and easy to diagnose. Automatic transmission fluid (ATF) is among the most complex fluids in a vehicle and gives life to the transmission. ATF lubricates transmission components to decrease friction and prevent overheating. It also functions as a hydraulic fluid, allowing gear engagement. If ATF begins to leak, the transmission will operate with low fluid, leading to an increased chance of overheating. This is the quickest way for a transmission to break down. If you see a pool of bright red fluid beneath your vehicle, take it to a transmission shop immediately.

Take note: if the fluid is dark brown or black and emits a seared odor, the fluid may be burnt. If this is the case, no minor repair or maintenance procedure can fix the internal failure already present. On the other hand, if the issue is simply a compromised transmission pan gasket, a transmission power flush, and pan/gasket repair can fix the problem for a few hundred bucks rather than a few thousand dollars!

Common Manual Transmission Problems

1. Clutch Drag Issues

The clutch is the primary interface between the driver, the engine, and the transmission. It is designed to wear out over time in order to save the transmission from excessive wear and tear. A clutch problem can feel like a transmission problem, but they are actually distinct parts with unique maintenance requirements.

When a clutch is failing, it can:

- Feel chattery when coming off the clutch

- Make noise when you push the pedal in or out

- Feel as though it’s slipping, like you are not fully engaging gears

- Abnormally hard to push the clutch pedal down.

If there are problems with the master and the slave cylinder (they work together), the clutch will go all the way to the floor with no resistance. Keep in mind that the throw-out bearing engages the clutch. The throw-out bearing and pilot bearing, which work together, should be updated when a clutch is being replaced. If there is squealing with the clutch pedal in, that could indicate a problem with both bearings. With most clutch replacements, it is necessary to resurface the flywheel, grinding them flat or replacing them if necessary. A dual-mass flywheel requires special attention, which is different from the treatment of a conventional flywheel.

2. Difficulties While Shifting

Hard shifting is a common standard transmission problem, and it’s usually a sign that something is either damaged or not adjusted correctly. Sometimes, this can be external to the transmission, such as when the shift linkage either breaks or has been knocked out of alignment. Difficulty shifting can also be caused by problems inside of the transmission itself when the various gears and bearings become worn over time and do not mesh correctly. Lack of (or the wrong) lubricant can also cause a manual transmission to stick or make shifting difficult.

The same thing can be true when a transmission jumps out of gear or fails to stay in gear after you let the clutch out. The various gears are not staying engaged, which can be a little scary if this happens to you while you are on the highway! Diagnosis requires a condensed version of our inspection process. There is never a charge for this because it gives us the information we need to tell you what needs to be done.

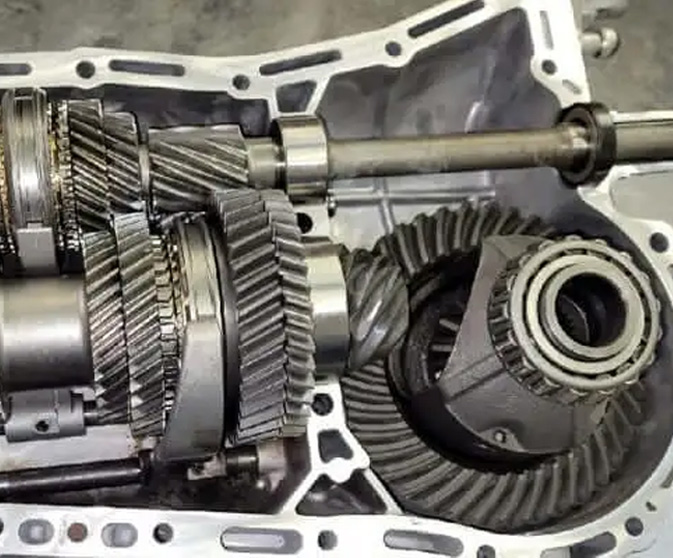

3. Making Noise When Shifting

A noisy transmission can often be the result of a transmission oil leak or a worn clutch disc, although these noises are typically only heard at certain engine speeds. Noises inside of a manual transmission are usually caused by worn or broken parts, such as the main shaft, gears with worn or broken teeth, worn bearings, worn synchros, or a worn pilot bearing. All of these parts are metal and will wear down as they work against each other over time. Not only does this increase tolerances between parts, which can lead to rattling, but it can eventually result in one of these parts breaking, which introduces metal fragments into the transmission that create grinding or squealing noises.

The important thing to remember is that noises inside of a transmission, especially a manual, are NEVER a good thing. It is a sign that internal damage has already occurred and a catastrophic failure is coming soon. Stop driving the vehicle and get it to a transmission shop immediately!

4. Check Engine Light is On

Whether you have an automatic or manual transmission, your vehicle’s Check Engine Light is designed as an early warning system to let you know when things are not working correctly and need to be seen by a professional. The service light on your dashboard is tied to a variety of sensors throughout your vehicle that monitor fluid levels, heat, pressure, and other operating factors. Manual transmissions tend to have fewer electronics and sensors than their automatic counterparts. If the Check Engine Light comes on, always assume that there is a good reason and get it into a reputable repair facility as soon as possible so that the cause can be diagnosed. Manual transmissions are extremely durable when driven appropriately compared to most automatic units, but they still require regular maintenance. Because of their reputation for reliability, many drivers ignore regular service and are surprised when issues develop.

5. Leaking Fluid

In an automatic transmission, fluid is essential to hydraulically shift between gears. A manual transmission works very differently, relying on the mechanical interaction of the various gears, synchros, and bearings. In a manual transmission, the fluid is present to lubricate these gears and to reduce heat caused by friction. Most manual transmissions use gear oil rather than transmission fluid. This is the same fluid often found in transfer cases or differentials. It generally has a much higher viscosity compared to ATF. As a result, leaking in a manual transmission usually does not result in a big puddle of fluid on the ground the way that it does in an automatic.

However, there is far less fluid inside a manual transmission, which means that a small drip on the floor or black film under the vehicle can turn into a serious loss of fluid in a hurry. When this happens, excessive heat develops, and parts that are not being lubricated overheat and grind together, resulting in premature transmission failure. Fluid levels on a manual transmission are more difficult to check, so make it a point to take your vehicle to a qualified shop for regular transmission service.

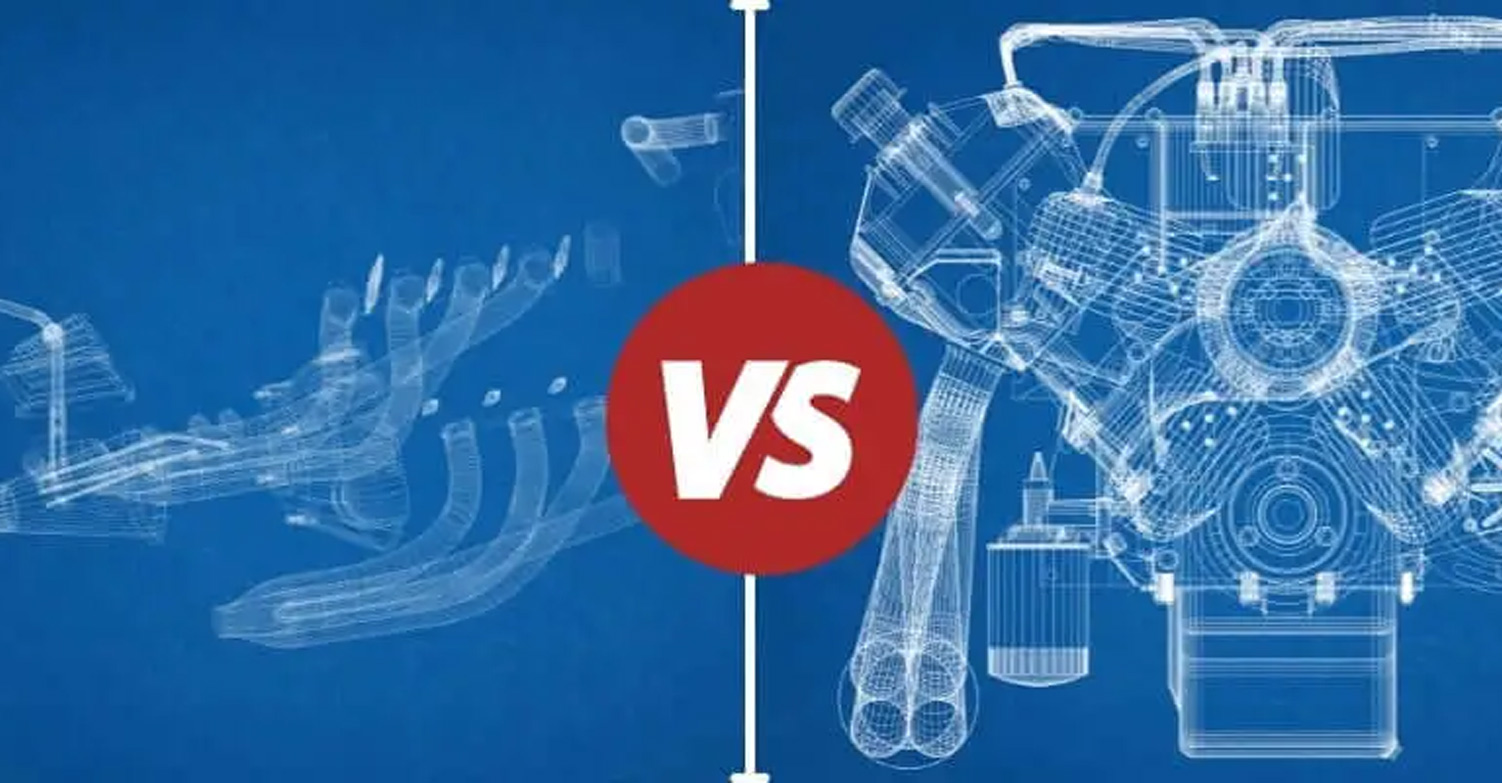

Transmission vs Engine Problems — Commonly Misdiagnosed Issues

Speed Sensor

A faulty speed sensor can no longer transmit the speed of the vehicle to the transmission and the associated computer systems. When this happens, the transmission on many vehicles will automatically go into limp mode, allowing you to still drive the vehicle, although slowly in a lower gear, until you reach the repair shop. Other symptoms include the transmission revving higher before shifting gear, engaging into overdrive late or not at all, braking harder than normal while coasting, an erratically behaving speedometer, or a confusing check engine light that lights up periodically.

Solenoid

The solenoid is a major component of the transmission and is responsible for shifting gears. This part can be replaced in some vehicles by removing only the pan, which avoids the cost of a full transmission rebuild, or by removing and reinstalling the transmission.

However, there are certain vehicles that do require full removal of the transmission to access the solenoid. Early transmissions from the 1960s even possessed a single solenoid that was critical to automatic shifts. Today, some transmissions have over a dozen solenoids. Some can be replaced individually, while others are integrated into a single solenoid block or the valve body itself.

Temperature Sensor

Similar to the speed sensor, if the temperature sensor is reading too hot or cold, it will trigger the transmission into limp mode. Other symptoms that could indicate this problem include poor fuel economy, black smoke from the engine, an engine that is overheating, and a check engine light.

Low Fluid Level

If the transmission fluid level is low and/or leaks, it can cause serious problems with gear shifting. If this is not corrected quickly, it can cause mechanical failure of the transmission and become an expensive repair. Any time you suspect a low fluid condition, it is best to have a transmission expert complete a service or flush instead of using a general auto shop. This will help ensure you get a correct diagnosis for the problem. In some cases, a transmission flush can cause more problems, so ask your transmission specialist if you should do a drain & fill, pan drop & full service, or a power flush.

Worn Engine Mounts

If an engine mount is worn or damaged, it can allow the engine to move and “slam” against the body of the vehicle when accelerating, making clunking or banging noises. Be aware–some repair shops could say the timing for shifting is off when the transmission really is okay. If the problem isn’t correctly diagnosed and fixed, it can quickly cause a lot of damage to many parts of the vehicle, including the transmission.

Engine Misfire

An engine misfire can lead to the check engine light turning on. There are many reasons that this particular warning light can go on, and one of them is spark plug failure or engine misfire. This can create symptoms similar to a bad transmission, where the machinery shudders during shifting.

Fuel Delivery System

When a vehicle does not rev past a certain point, it can indicate a damaged fuel delivery system. However, sensors in the vehicle may monitor the accelerator pedal instead, leading to a misdiagnosis of transmission failure. If you hear a loud electrical clicking or whining when the engine is running, even at idle, chances are excellent the fuel delivery system is the culprit.

Restricted Air Flow

Air flow is critical for the proper performance of a vehicle. A failure in the catalytic converter can cause an exhaust system restriction and lack of acceleration. This may be due to antifreeze entering the combustion chamber or an improper fuel-to-oxygen ratio. If the converter outlet becomes plugged, it will ultimately lead to a lack of power, causing misdiagnosis of a transmission problem.

Preventative Care – Routine Car Maintenance

1. Transmission Fluid Maintenance – Car Cooling System Maintenance

A transmission has hundreds of moving parts and generates a tremendous amount of heat. A key responsibility of transmission fluid is to manage that heat. Even though transmission fluid has become increasingly complex, even the best transmission fluids in the market need assistance. The vehicle’s cooling system provides that help.

The radiator and/or external cooler are both designed to accept hot transmission fluid and cool it before sending it back to the transmission. Like most components in a vehicle, a cooling system should be periodically inspected and maintained. If a radiator is low on fluid, commonly known as antifreeze or coolant, it will not be able to cool the transmission fluid. This will lead to a transmission overheating.

Also, the fluid lines to and from the transmission to the radiator need to be periodically checked for leaks. A small leak over time leads to a transmission that is low on fluid. Eventually, there will not be enough fluid to manage and absorb the heat generated from the transmission, and the unit will overheat.

Finally, a crack in the radiator can be disastrous for a transmission. This is a common occurrence in the Nissan Xterra, Nissan Pathfinder, and Nissan Frontier models in certain years between 2000-2010. The radiator is known to develop a crack, causing radiator coolant to enter the transmission lines. Once that coolant and water mixture enters the transmission, a major repair bill is on the horizon as the resulting fluid within the transmission has a pinkish tint, which industry professionals jokingly call “strawberry milkshake” fluid.

The intrusion of glycol within the system leads to rust on major components and requires a full transmission rebuild or replacement. The RE5R05A transmission includes a valve body requiring dealer reprogramming, and the entire job – radiator replacement included – could be north of $5,000. Avoid these types of situations and ensure your cooling system is regularly inspected and maintained.

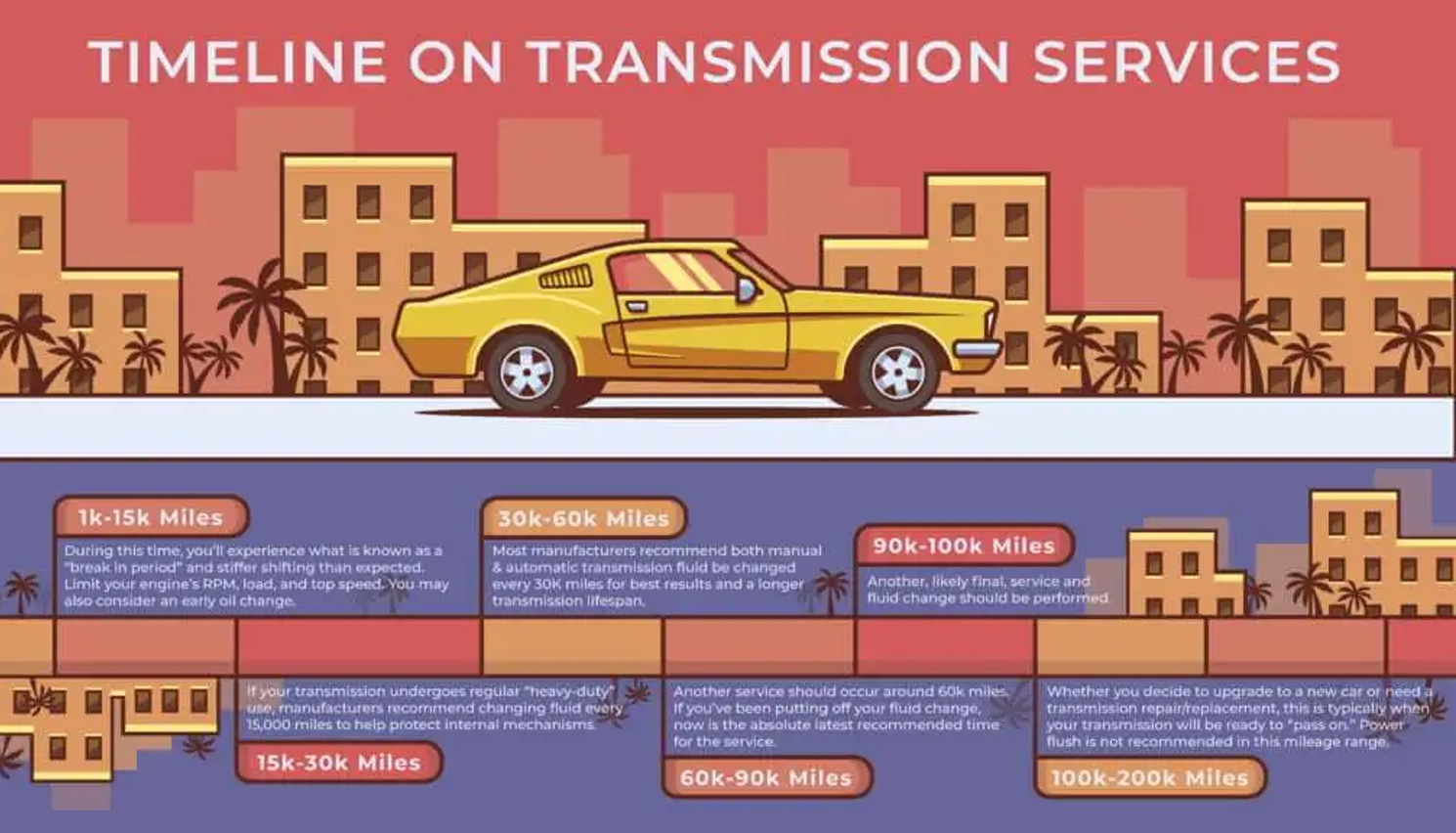

2. Regular Transmission Servicing

Transmissions do the most complicated work of the vehicle. It only makes sense to service it at regular intervals. A transmission service should include dropping the transmission pan, completing a partial drain of the fluid, replacing the transmission filter, and replacing the gasket to the pan. Between one-third to two-thirds of the original fluid stays in the transmission because fluid from the torque converter does not come out during a drain-and-fill procedure.

This is ideal for higher mileage vehicles because new fluid is introduced to the system and mixed with the old fluid, minimizing any potential shock to the transmission. A service should generally occur every 30,000 miles. If a vehicle carries a load, operates in stop-and-go traffic, or travels across dramatic elevation changes, a more frequent service interval is recommended.

All Colorado driving is considered “severe” from a vehicle maintenance perspective, given the altitude, lower air density, and higher chance for a vehicle to overheat. For lower-mileage vehicles, a Power Flush is a great solution to add longevity to a transmission in the early life of your vehicle. This is not recommended for vehicles with over 100,000 miles. We suggest consulting your local transmission shop for advice on a proper maintenance schedule based on your geography and the application of your vehicle.

3. Replacing Transmission Fluid with OEM-Specified and High-Grade Fluid:

There are dozens of transmission fluids formulated for the hundreds of transmissions on the road. Do not make the terrible assumption that all transmission fluids are the same, and put a generic transmission fluid in your vehicle – it will be a costly mistake!

Transmission fluids have specific properties involved in temperate management, clutch engagement, and hydraulic operations, among other responsibilities. Always default to the OEM specifications for a fluid type and, if anything, upgrade the fluid. All recent makes require a full synthetic fluid. However, we recommend all vehicles make the switch to a full synthetic to increase the useful life of a transmission.

Pros and Cons of Various Types of Transmission Repair

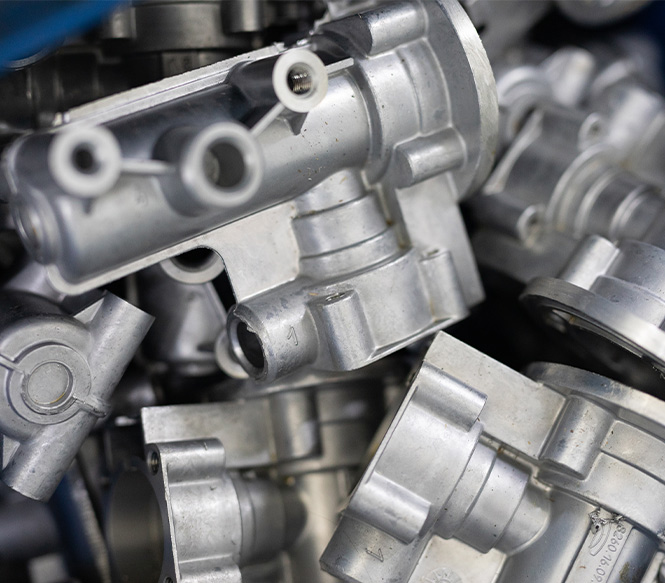

1. In-House Rebuild

A rebuilt transmission can go by other names, such as refurbished or reconditioned. What it means is a transmission that is fully disassembled with all parts cleaned and inspected for wear. Those that are worn or damaged are replaced. The transmission is then put back together, filled with fluid, and reinstalled. In some cases, the transmission may require special reprogramming so that the onboard computer can communicate properly with the new transmission. A benefit to rebuilding a transmission is the availability of new or updated components that can be installed. This can fix weak areas and known problems, making them less likely to fail again.

Unfortunately, there is no way to visually confirm if a shop did a good job or not since the transmission’s interior parts are all enclosed. This is why it’s important to choose a shop like Advanced Transmission Center that can be trusted to do a thorough, honest repair at fair prices. Many shops often advertise themselves as “affordable” or “budget,” yet these gimmicks often leave customers with an unreliable “spot repair” and a vehicle breakdown around the corner.

A quality transmission shop has its own in-house rebuild department. By doing all the work ourselves, we control the quality of the rebuild and repair of every transmission, transfer case, and differential that leaves our shops. We make sure that only the highest quality parts are used. Customers should definitely research before choosing a shop to rebuild their transmission.

For decades, this was the preferred option for vehicle owners who expected a transmission rebuild every 50,000 miles on vehicles produced in the 1960s and 1970s. A transmission rebuild was viewed as a maintenance activity every few years rather than a catastrophic stroke of bad luck, the perspective of most customers walking into a local transmission shop these days.

2. Remanufactured Unit

A remanufactured transmission is essentially the same as a rebuilt transmission but is usually done in a factory by a team of specialists who each have a specific job similar to an assembly line. For instance, one might pull it apart and drain the fluid. The next might clean all the components, while the third checks them all for wear or damage down the line until it is reassembled and sold to a retail outlet. In some cases, the “specialist” may only build one model of transmission from beginning to end; this often leaves the specialist lacking the diagnostic capabilities and perspective necessary to be an elite transmission repair specialist.

The quality of a remanufactured transmission varies greatly between brands and even within a factory, where dozens of rebuilders are likely to have differing levels of expertise. These factors reinforce our view that a locally rebuilt transmission by a team you can directly engage with is your best option. In some circumstances, a remanufactured unit could be a viable option. This reality encouraged Advanced Transmission Center to team up with Certified Transmissions to provide the occasional remanufactured transmission to customers.

3. Spot Repair

A “spot repair” is a situation where the transmission is disassembled in order to find one or two broken or worn-out parts that have failed. Thereafter, those parts are replaced, and the unit is put back together. While this is certainly less expensive than having a full rebuild done, it also creates several potential problems in the not-so-distant future. A transmission is a tremendously complicated system of parts working together, and they don’t wear out independently.

Additionally, when one part fails, it has a cascading effect on the rest of the system. That means that while you might have saved money by having a spot repair done, there is a very good chance that other parts are going to fail soon. As a result, you will have to pay to have the transmission pulled and repaired again. It won’t take long for you to have paid significantly more for repairs than you would have if you had the transmission rebuilt properly the first time.

Sometimes, saving money right now will end up being far more expensive in the long run! Examples of this type of repair should be replacing a torque converter or swapping out a valve body. In the rarest of circumstances, this could make sense, but most of the time a disaster is down the road. Many cheap transmission shops lure their customers in with low prices because they invest very little in the rebuild; these are the shops to avoid because they often avoid warranty claims.

4. Used Unit

A used transmission can be another option that at first appears to offer decent cost savings. This involves buying a transmission out of an older car, most often through a junk or salvage yard. Usually, they come with a very limited warranty, such as a few months or a few thousand miles, whichever comes first. Most used transmission warranties do not cover labor. When you get a transmission from a junkyard, it’s really hard to know what you are getting. You don’t know the history of the vehicle it is coming out of or how that vehicle was maintained. You risk having it fail and going through the whole process again. Even if it fails while under warranty, you are probably going to have to pay the labor cost AGAIN to remove and replace the transmission. If it is out of warranty after a short period of time, you are now right back where you started and have paid a considerable sum to only get a few months of driving after the repair.

Transmission specialists will often install a used unit for budget-constrained customers, but the customer risks having to pay multiple times for the removal and installation of potentially bad, used transmissions. Again, it won’t take long before you will have spent far more than it would have cost to have it properly rebuilt the first time. Many unethical general automotive and transmission shops will install a used transmission but tell a customer they are buying a rebuild. Sadly, customers often won’t know the difference and risk being taken advantage of. This is why working with a trusted transmission repair brand is so important.

Conclusion

Transmissions are continually changing because they are the central system that allows a vehicle to gain improved fuel economy, an objective shared by many policymakers and consumers. These changes may come with higher vehicle MPG results; however, they may be achieved at the expense of durability. A responsible vehicle owner needs to understand (1) good maintenance habits for a transmission, (2) symptoms of a transmission requiring immediate attention, and (3) options for transmission repair.

Your repair options depend on the type of shop you visit. Most transmission specialists, including the Advanced Transmission Center team, will advise customers that using transmission replacement is a terrible idea. General automotive shops do not maintain the capability to rebuild transmissions internally. Therefore, they are more likely to buy a cheap junkyard transmission and mark it up substantially. This is a major reason to trust a local transmission repair shop with accreditation from a national organization, such as the AAA or ATRA (Automatic Transmission Rebuilders Association). We are proud to be the only brand in Colorado with accreditation from both organizations!

Since 1986, Advanced Transmission Center has been “Geared for Customer Satisfaction!” We don't just know how to fix transmission problems; we specialize in the vehicle drivetrain, which includes transmissions, transfer cases, and differentials. Our team aims to be the best in our specialty, and we continue to invest in the most recent technology to handle the increased complexity associated with drivetrain and transmission repair. We look forward to servicing your vehicle and adding you to our long list of satisfied lifelong customers!

-

Northwest Denver Repair Facility

(303) 421-4140

3686 W 72nd Ave, Westminster 80030 -

Southwest Denver Repair Facility

(303) 922-4102

1194 S Pierce St, Lakewood 80232