History of the Torque Converter

Early transmissions required some “manual” operation in order to work. The engine was directly connected to the gearbox and the rest of the driveline, the vehicle would stall any time that the vehicle came to a stop. In order to come to a stop and keep the engine running, a clutch was used to separate the connection between the engine and the gearbox. This manual system was used from the invention of the automobile up until the 1930’s.

A German engineer by the name of Herman Fottinger devised and received a patent in 1905 on a fluid drive and torque converter, beginning the move towards an “automatic” transmission. Fottinger licensed his torque converter to a number of companies in the 1930’s, including the Chrysler Corporation. In 1939, General Motors became the first manufacturer to use a fluid drive in a mass-produced automobile when they introduced their Hydromatic transmission.

How Does a Torque Converter Work

A torque converter works as a fluid coupling system that takes the place of the clutch in a manual transmission. It allows the engine to turn independently from the transmission. When you are at a stop, the engine is turning slowly and the amount of torque going through the torque converter is low. As you step on the gas and the engine revs higher, the amount of torque transmitted to the torque converter increases and the vehicle begins to move.

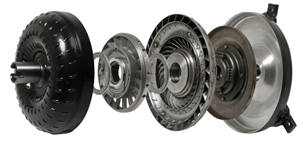

So, how does a torque converter work? A torque converter is basically made up of an impeller, turbine, stator, clutch, and transmission fluid. The impeller has blades like a fan and is turned mechanically by the engine. As the engine picks up speed, the impeller spins faster which in turn pushes the transmission fluid faster.

The transmission fluid then hits the turbine, which is a fan similar to the impeller and turns the transmission shaft. The problem with this is that the transmission fluid is moving in the opposite direction of the engine, so it will begin to drag on the torque converter housing and slow everything down. That brings us to the stator, which is another fan-shaped device that takes the transmission fluid in and reverses direction, reducing drag and increasing efficiency in the unit.

The last piece, the lock-up clutch, allows the impeller and turbine to lock together at higher speeds which reduces slipping and in turn increases the fuel efficiency of the system. Packard and Studebaker had used a lock-up clutch back in the 1940’s, but the design was dropped due to the increased cost of production. However, the fuel shortages of the 1970’s forced automakers to look at ways to increase fuel efficiency. The lock-up clutch was reintroduced by Chrysler in 1978 and General Motors followed suit in 1979. Since then, the lock-up torque converter has become an industry standard.

A torque converter works when all of these pieces combine to allow the unit to take the power of the engine and transmit it as needed to the transmission gear assembly. The torque converter works in 3 phases: stall, acceleration, and lock-up. During “stall”, the engine is turning as is the impeller. However, the turbine is not moving and as a result, the vehicle does not move. During the acceleration phase, the engine drives the impeller and increases the velocity of the transmission fluid, which in turn increases the speed of the turbine (and thus the rest of the vehicle). The final lock-up phase usually occurs at speeds above 40 miles an hour and allows the engine and transmission to turn at the same speed, without any residual slipping or loss of efficiency.

Symptoms of a Bad Torque Converter

The complexity of the parts working inside of a torque converter means that they do in fact give out over time. There are some symptoms of a bad torque converter you need to monitor:

- Leaking – The complexity of the parts working inside of a torque converter means that they do in fact give out over time. High heat can warp the outside case of the torque converter and can cause the seals to break down, which will result in leaks. As transmission fluid leaks out of the torque converter, there is less fluid inside which results in even greater heat and more damage.

- Slipping – As a torque converter breaks down, it can cause problems for the transmission shifting from one gear to the next. Rather than a clean shift, you might feel a delay in shifting and see the engine rev higher as it tries to engage another gear.

- Overheating – The pressure inside of a torque converter creates heat, and heat will eventually cause the torque converter to break down. Some vehicles have a transmission temperature warning light, and this will come on when the temperature gets too high. Overheating can also cause the vehicle to go into “limp mode”, where the vehicle will stay in one gear (usually 2nd or 3rd) and will not shift at all.

- Shuddering – A classic symptom of a bad torque converter is a shudder. The breakdown inside of the torque converter creates an imbalance in the flow of the fluid, which creates a shudder that feels almost like you are riding on a dirt road or over a rumble strip. The sound and the vibration of a torque converter shudder are signs you need to get it inspected quickly!

- Transmission fluid contamination – High heat, pressure and wear over time will cause the parts inside of a torque converter to break down. When this happens, the fluid will carry these small particles throughout the rest of the transmission. The transmission fluid will get dark, will often smell burnt, and you will be able to see the contamination in the fluid when checking the dipstick.

Transmission Specifics: The 6L80 (and the similar 6L90) transmission from General Motors was introduced in 2005 and is still used today. A six-speed transmission designed for use in rear wheel drive vehicles, it has been used in Chevrolet and GMC pickups, the Cadillac Escalade and GMC Yukon Denali, and the high-performance Chevrolet Camaro and Corvettes. Over the years, the 6L80 has become well known for torque converter issues leading to transmission failure. A design flaw in early models leads to consistent wear between the torque converter cover and the lock up clutch. That creates high heat, shuddering, and eventual breakdown of the case itself which spreads metallic pieces throughout the transmission.

If you are experiencing one of these symptoms of a bad torque converter, give us a call!

Torque Converter Repair

The good news is that we are here to help! The Advanced Transmission Center team consists of technicians who have decades of experience diagnosing, rebuilding, and repairing automatic transmissions in domestic and import vehicles. We are your local transmission repair shop and we are the most trusted specialty shop for local dealerships and general automotive repair shops. We have the ability to test and diagnose problems with your torque converter and use only quality parts in our torque converter repair.

In some cases where a particular torque converter is known to have problems, Advanced Transmission Center may recommend using a heavy-duty billet aluminum torque converter. Two reasons motivate the use of billet torque converters: faulty designs and HD applications. There are cases where the OEM design is known to have weaknesses that lead to premature failure and an upgraded torque converter might be the solution to get your vehicle back on the road. In addition, a billet torque converter works well for vehicles facing load applications near or beyond its OEM limits. This is particularly a great option for construction vehicles, trucks that tow, offroad vehicles, vehicles that plow snow, work trucks, etc.

At Advanced Transmission Center, EVERY in-house transmission rebuild includes a fully remanufactured torque converter. Unlike second-tier transmission repair shops, we believe the integrity of a rebuilt transmission is compromised if the old torque converter is reused. We partner with a local Denver-based machine shop that exclusively focuses on rebuilding automatic torque converters.

If you are having problems with your torque converter or any other transmission-related issue, contact Advanced Transmission Center at either of our locations and we’d be happy to help! Unlike dealerships or many independent repair shops, we are transmission specialists trained to fix issues related to a vehicle’s drive-train. You can reach out to either location that is most convenient for you.

Advanced Transmission Center is a Colorado-owned and operated auto repair shop with locations in Denver / Lakewood and Westminster. ATC specializes in driveline issues such as automatic transmission repair, four wheel drive repair, clutch replacement, differentials, manual transmissions and CVT. As Colorado's first AAA approved shop our goal is to provide accurate, timely service with exceptional customer satisfaction. All of our technicians are certified in the latest makes and models and we are one of the few transmission repair shops with a nationwide warranty.

Free Customer Towing Service

Free Customer Towing Service  Free TrueTest™ Inspection

Free TrueTest™ Inspection  Fast Transmission Services

Fast Transmission Services  Comprehensive Warranty in Denver

Comprehensive Warranty in Denver